Hop Gun Working process in Brewery

This equipment is used in the production of strongly bitter beer types, such as IPA (India Pale Ale).

Dry hopping is the addition of hops to beer during the fermentation process, conditioning procedure, or when the beer is in the serving vessels.

Many beer styles require the addition of hops at certain brewing stages.

When hops are added to the brew at the start of the wort boil, it contributes to the production of bitters - a beer with a more stringent taste.

When hops are added during the mid-point of the boiling process, it imparts some bitterness, but also aromatics.

Late-hopping is when the hops are added at the final stages of the boiling. This can result in a hoppy, aromatic beer, full of flavor. However, it can also result in a bitter beer with a rounded flavor.

Using a hop cannon is a great way to get more character from your hops into your beer, in less time, while adding fewer hops.

It provides better efficiency and quality, reduced dissolved oxygen (DO) levels in the finished product, and a safer working environment for the brewers.

Ultimately this means less oxygen is introduced to the beer, and there is a more consistent dissolution of hops pellets than with traditional methods.

Employing a hop cannon is an effective improvement to the standard dry-hopping process.

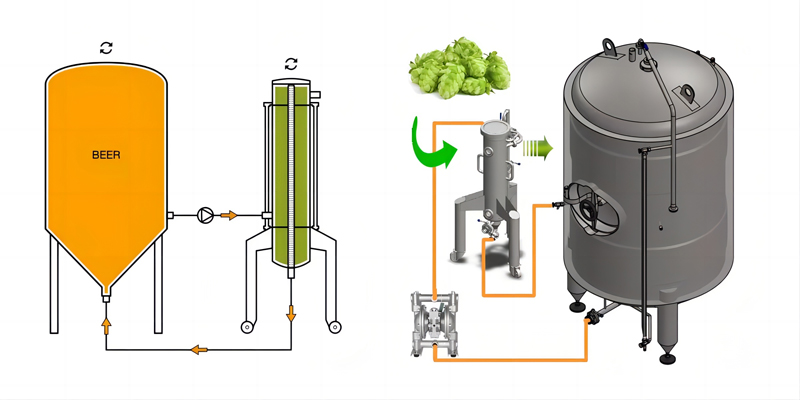

Instead of a brewer climbing to the top of a fermentation vessel and dumping a bag of hops pellets into the top port, the hops are safely and conveniently added to the hop cannon vessel.

Once the hop pellets or other ingredients imparting their aroma to beer are placed into the HopGun, the air is purged from the system, and it is pressurized with CO2 prior to being filled with beer.

The beer is then pumped from a tank and fed tangentially into the Hop Gun, whereupon it flows back into the tank and continues to do so in a circuit.

The pellets in the Hop Gun are set in motion, being subject to the turbulent flow of the beer.

As the constituents from the pellets dissolve in the beer, a filter cartridge retains the solids in the Hop Gun, allowing only the finely dissolved particles to pass into the tank.

This is the means for the highly effective extraction, thus reducing the amount of hops or other ingredients necessary for imparting aroma to beer.

Compared to static dry hopping, savings of 25–40 % are possible.

Depending upon the which ingredients are used, the solid material can either be partially or completely retained in the system.

The individual filter cartridges determine the extent of the retention.

Advantage of Hop Cannon

1.Avoid oxygen pick-up

2.Better aroma pick up

3.Dry hopping under pressure

4.Use less hops

5.Save more beers

What Temperature is the Beer at When Using the Cannon?

This is truly personal preference; all brewers have their own beliefs and methods.

Experienced brewer usually run a cannon at 17°C (62.6°F).

Generally, the warmer the beer the more aroma will be picked up. Most brewers tend to dry-hop in the 17 to 21°C (62.6 to 69.8°F) range.

Although, some brewers dry hop at 10°C (50°F). While 17°C leads to less chance of polyphenol extraction, astringency or hop bite.

What Pressure When Using the Cannon?

Over time the candle gets a little clogged with pressure starting to rise in the cannon,

we suggest to start with 4 PSI (0.27 Bar) or even lower in the FV/unitank where the beer is being held, and the maximum pressure in the hop cannon is under 25 PSI (1.7 Bar).

Which is high but still within safe parameters.

Conclusion

The hop cannon is a testament to the creativity and innovation in the craft brewing industry.

Its ability to precisely control hop additions and enhance aroma and flavor makes it a valuable tool for brewers striving to craft exceptional and consistent beers.

Whether used for hop-forward IPAs, delicate pale ales, or any other beer style, the hop cannon has earned its place in the brewery as a gateway to unique and unforgettable flavors and aromas.

Jinan Alston Equipment Co.,Ltd.

Jinan Alston Equipment Co.,Ltd.